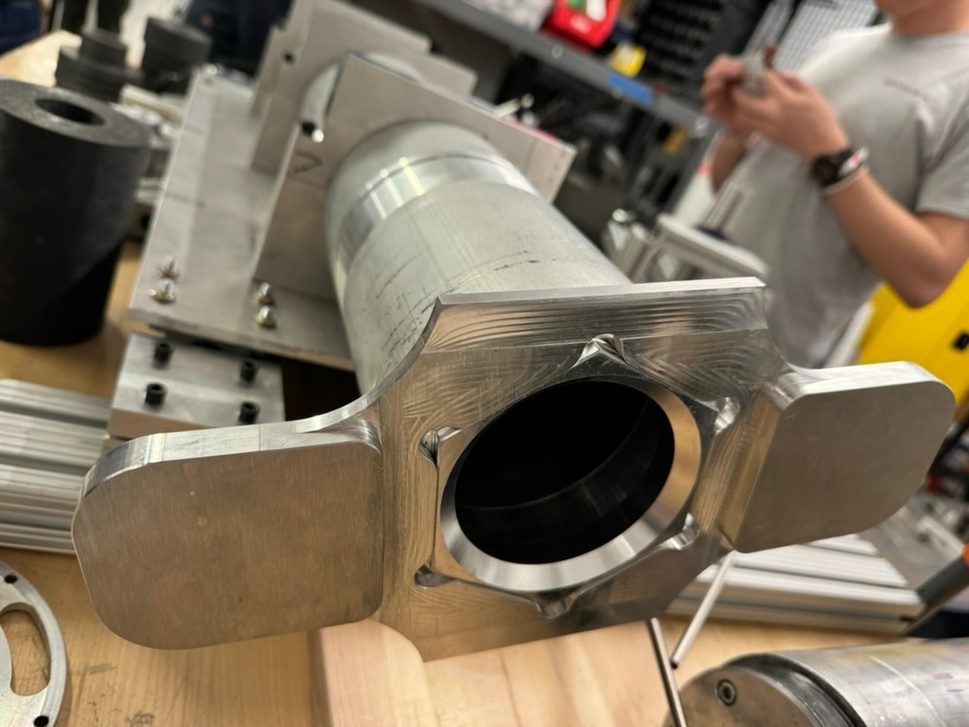

Hybrid Injector Assembly

Hybrid Injector body and plate that I machined on the HAAS

As Hybrid Propulsion Lead, I led the design, development, and testing of both subscale (260 lbf) and full-scale (950 lbf) hybrid rocket engines. This project involved extensive CNC machining, MATLAB simulation development, and successful hot fire testing.

Project Overview:

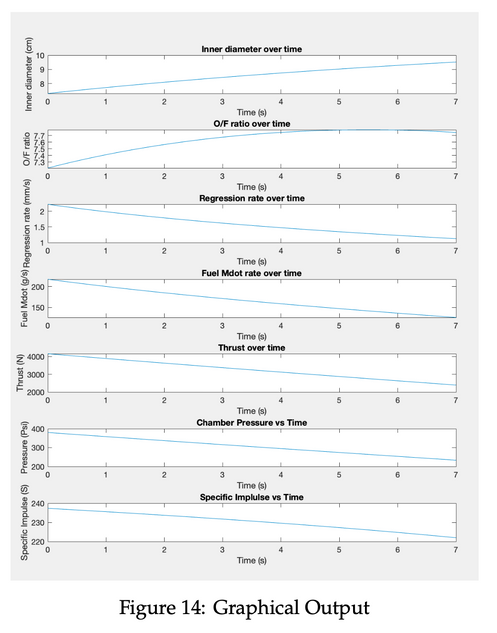

The 260 lbf hybrid rocket engine was designed as a scaled test to validate key components of our hybrid motor design, specifically the injector, liner, and nozzle. We also aimed to verify the accuracy of our hybrid engine simulation script by comparing its predictions to actual hot fire test results. The simulation proved highly accurate, predicting the peak thrust within 10 lbf of the measured value.

Following the success of the 260 lbf test, which confirmed the integrity of our design, we redesigned the engine to target a thrust output of 950 lbf, utilizing the same design script. We also re-engineered the injector and retention ring to reduce manufacturing complexity.

We conducted two hot fire tests with the redesigned motor, achieving a peak thrust of 400 lbf. The discrepancy in thrust was due to the injector plate lacking the correct number of orifices.

To address this, I revisited the injector design, refining our injector plate calculations based on both the hot fire data and insights from the Benjamin Waxman paper on nitrous oxide injectors. These updates improved the accuracy of our predictions for future tests and ensured better alignment between our theoretical models and experimental outcomes.

Key Action Items:

Skills: Project management, CNC machining (3- and 4-axis HAAS mills), Solidworks CAD, MATLAB simulation, hybrid rocket design, injector design, pressure vessel design, hot fire testing, data analysis

Hybrid Injector body and plate that I machined on the HAAS

Manufactured threaded nozzle retention ring on HAAS mill

Designed and machined wrench to install nozzle retention ring

Designed and machined oxidizer tank bulkhead

Assembled oxidizer tank

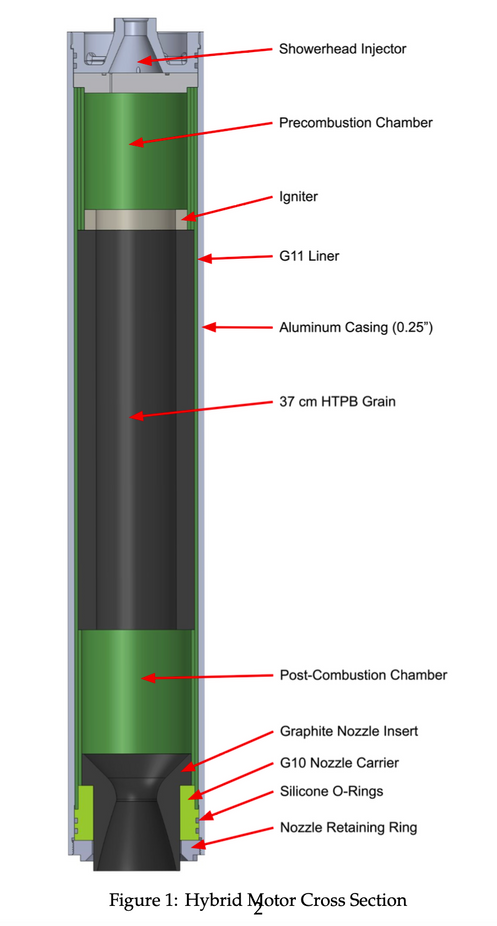

Full Scale Hybrid Rocket Engine design and Simulation output

MATLAB simulation results and design validation

I developed a comprehensive MATLAB hybrid rocket design tool that calculates fuel grain dimensions, oxidizer load, throat diameter, and thrust predictions. The simulation proved highly accurate, predicting peak thrust within 10 lbf of the measured value during hot fire testing.

The simulation incorporates:

Hybrid Rocket Engine Technical Report - Spring 2024

Comprehensive technical documentation of the 260 lbf and 950 lbf hybrid rocket engine development, testing, and validation process.