Helios Engineering Internship

Key Action Items:

- Designed vacuum furnace lift in Solidworks, outsourced machining of components and successfully installed device

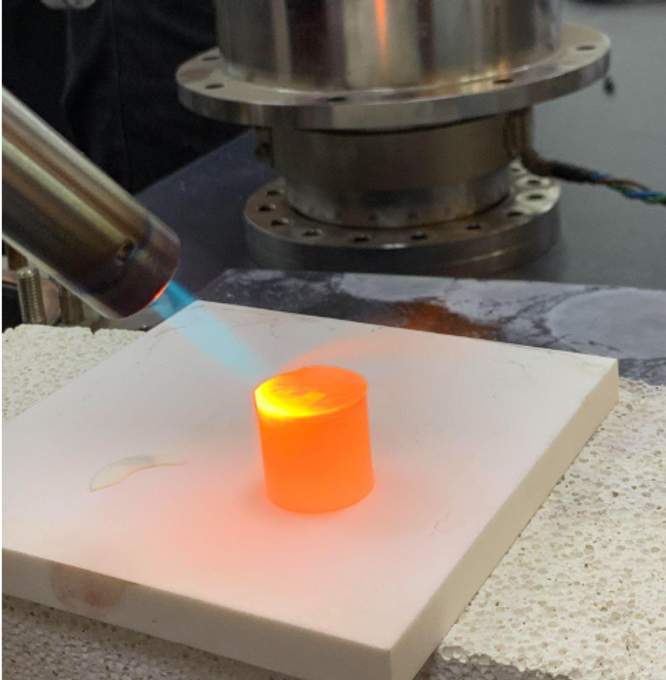

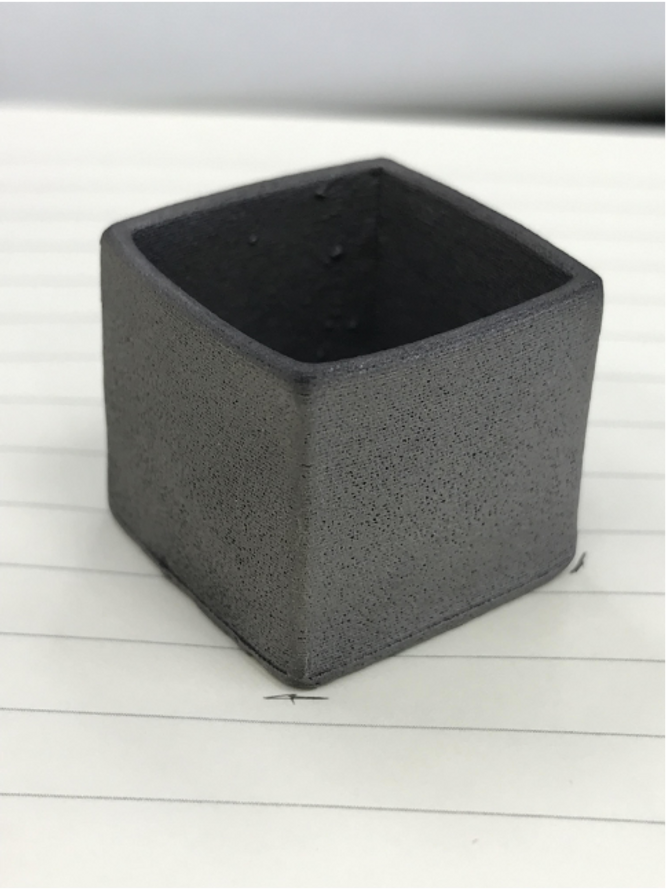

- Conducted research and successfully developed a procedure to 3D print components in-house with novel ceramics

- Supported lab team with rapid prototyping and taught co-workers how to 3D print with FDM and resin printers

- Created vacuum assemblies to withstand temperatures up to 1900°C to enable material science experiments

Helios Engineering Technical Documentation

Bumblebee AI (now BloomX) artificial pollination internship

Key Action Items:

- Designed several critical components of the pollination device using Solidworks

- Traveled to Mexico for a field trial and brainstormed solutions to reduce part breakage while in the field

- Optimized 3D printer parameters to fabricate production quality parts, while minimizing filament use

- Took charge of constructing electronic control boxes, modified circuit diagrams and wired components

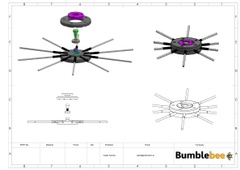

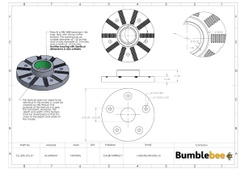

Bumblebee AI CAD/Drawings

- 1. Electronics enclosure

- 2. Vibrating pollination wheel assembly

- 3. Metal pollination wheel drawing

Bumblebee AI CAD Design Work