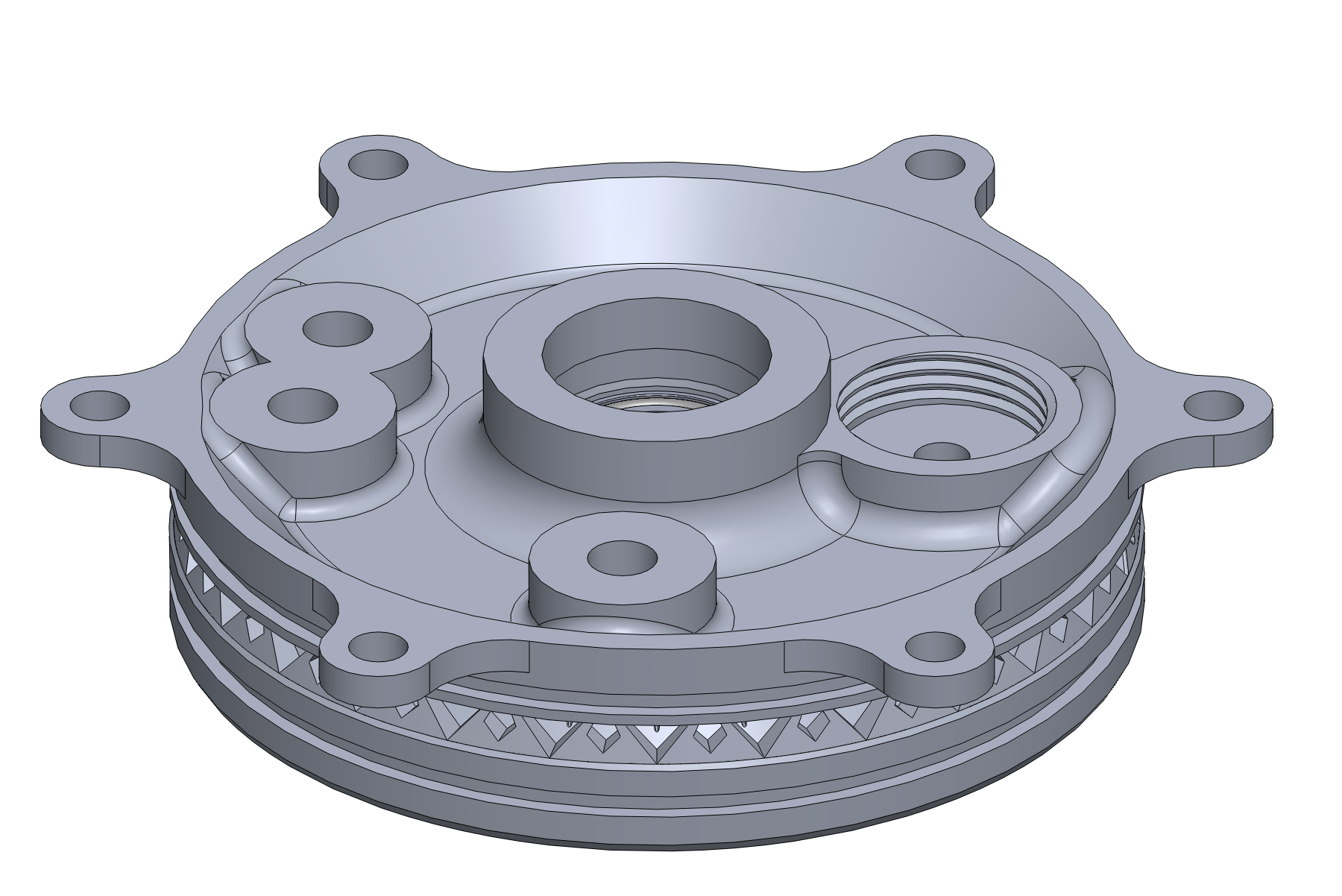

Internal Cooling Channels

Detailed view of regenerative cooling manifold design

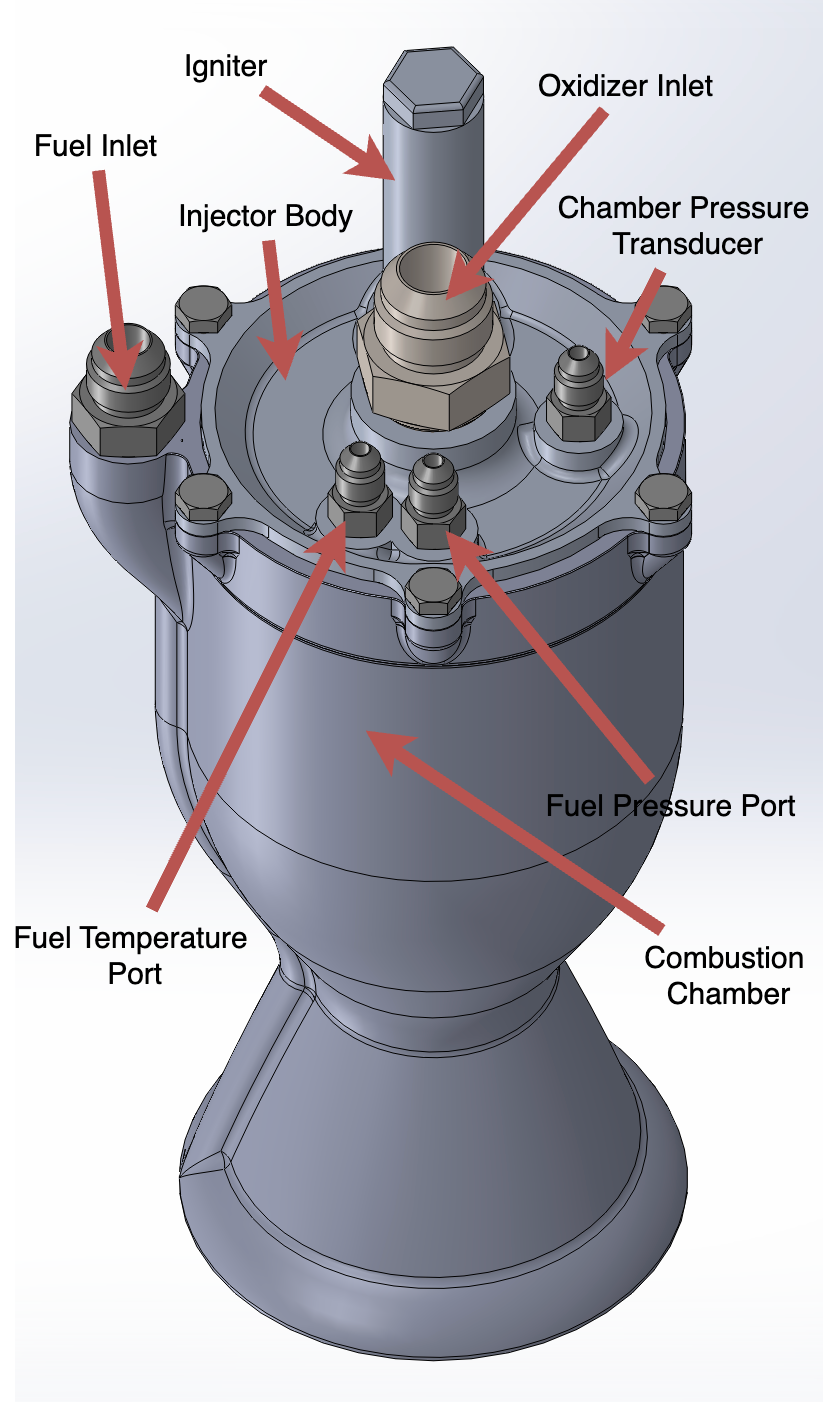

Designed Cornell's first 1,250 lbf ethanol/N2O regeneratively cooled bipropellant rocket engine, introducing the team to cutting edge propulsion technologies and metal additive manufacturing techniques. This engine was designed in RPA V4.0, and then modeled in solidworks and analyzed in ANSYS mechanical and Fluent. The main focus of this project was to rapidly develop a functional engine that could be tested with minimal modifications to existing test stand hardware and electronics.

Project Overview:

This project involved the design, analysis, and manufacturing of a additive manufactured regeneratively cooled bipropellant rocket engine. The engine utilizes ethanol as fuel and nitrous oxide (N2O) as oxidizer, with regenerative cooling to manage the incredibly high heat flux during operation.

Detailed view of regenerative cooling manifold design

Full 3D assembly showing combustion chamber, injector, and cooling manifold integration

Isometric view of the ethanol injector manifold with cooling channel integration

Chamber top view showing injector interface and ethanol fuel port.

Nozzle view showing cooling manifold.

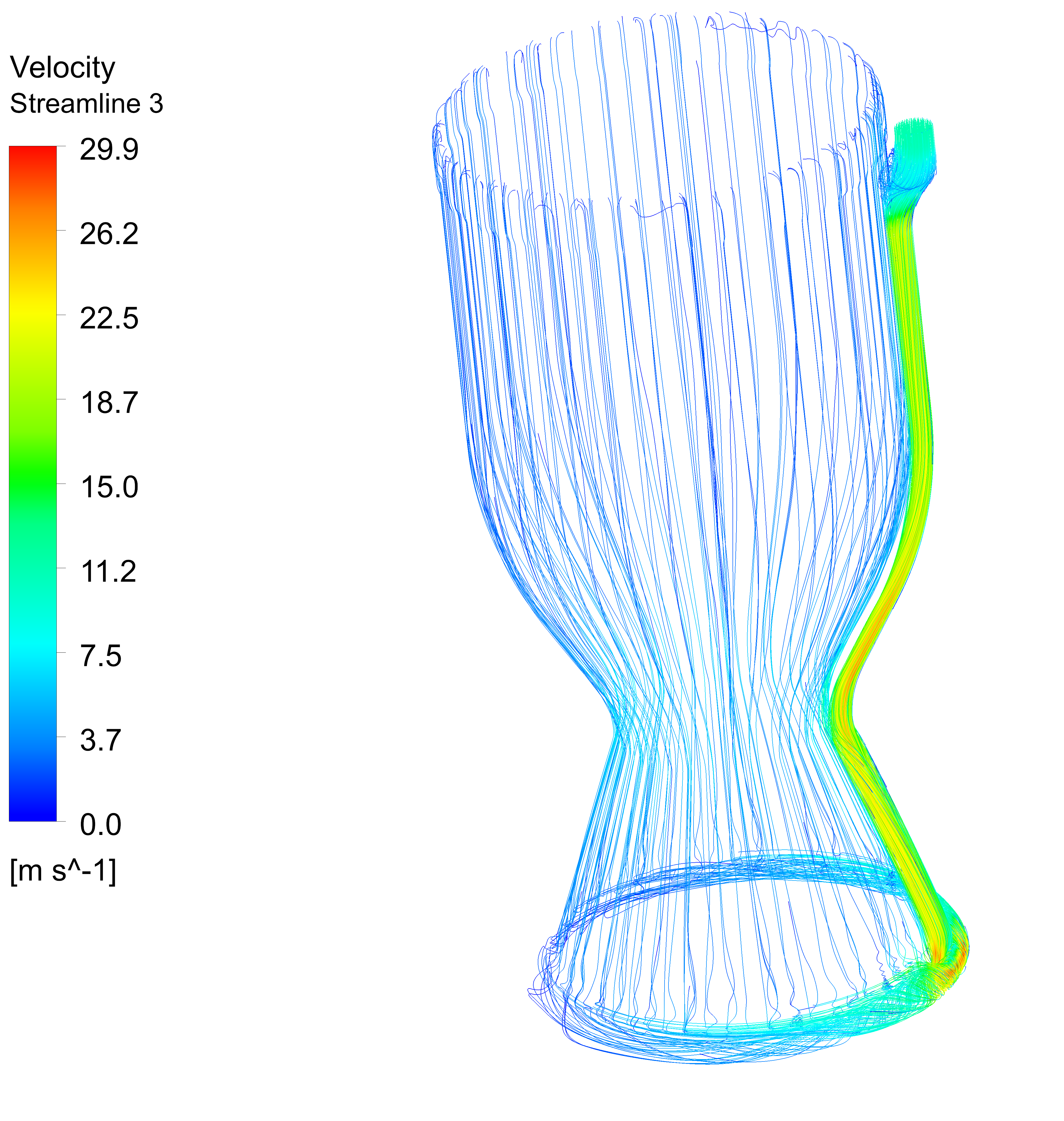

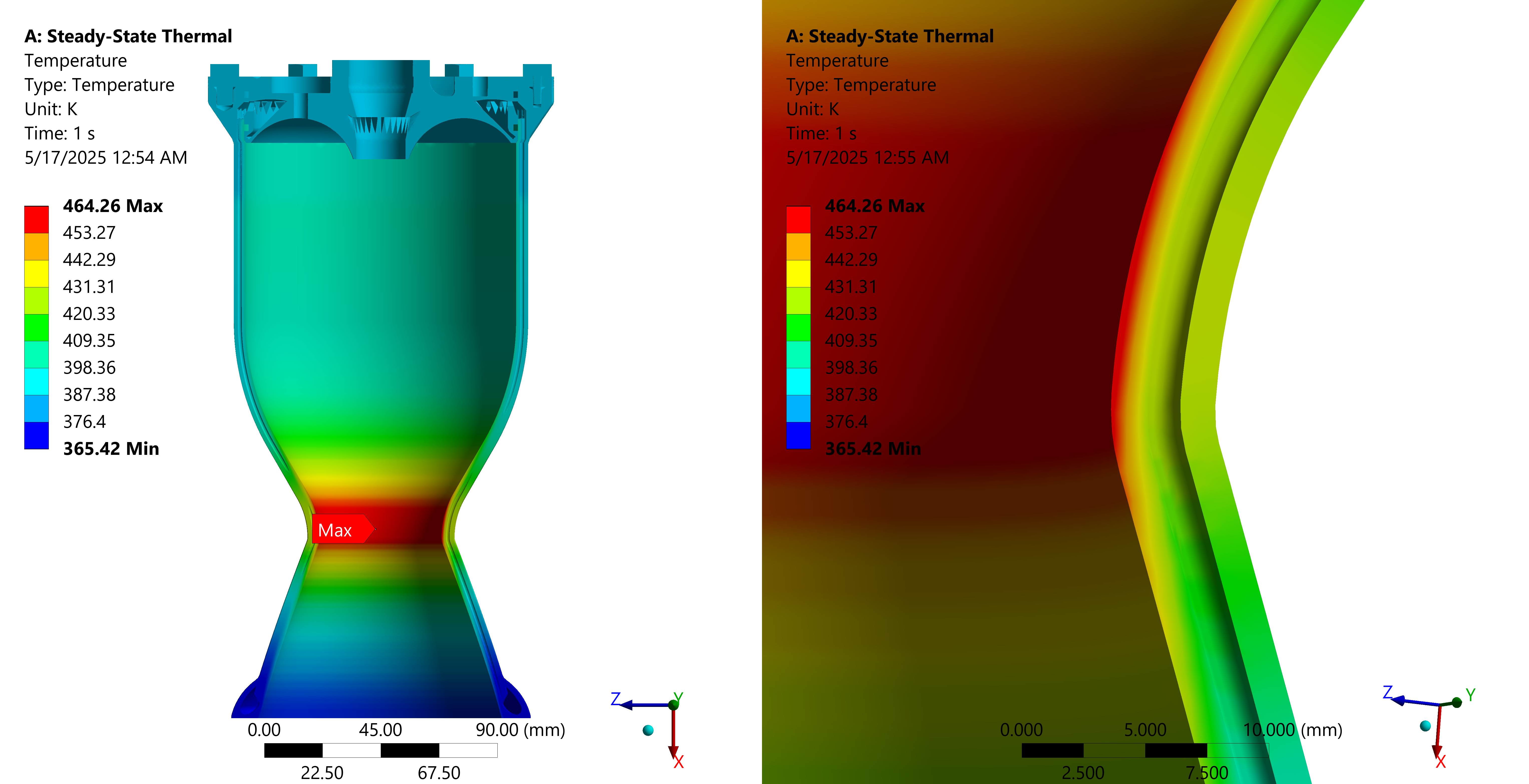

Performed comprehensive computational fluid dynamics analysis using ANSYS Fluent to validate the regenerative cooling system design and ensure thermal limits are maintained throughout the engine operation. Combined with structural analysis to optimize design under both thermal and mechanical loading conditions.

CFD streamlines showing ethanol coolant flow through regenerative cooling channels

Steady-state temperature distribution showing temperature gradients across the chamber and nozzle

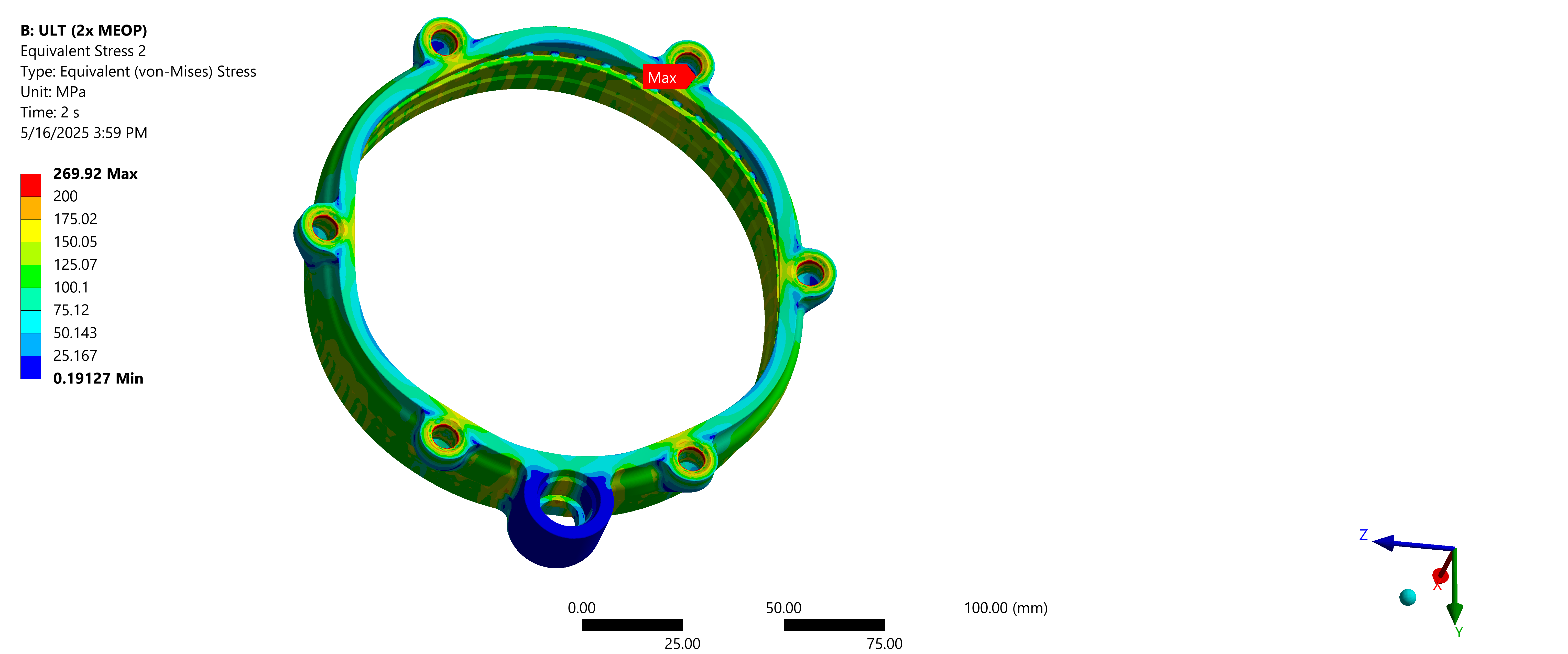

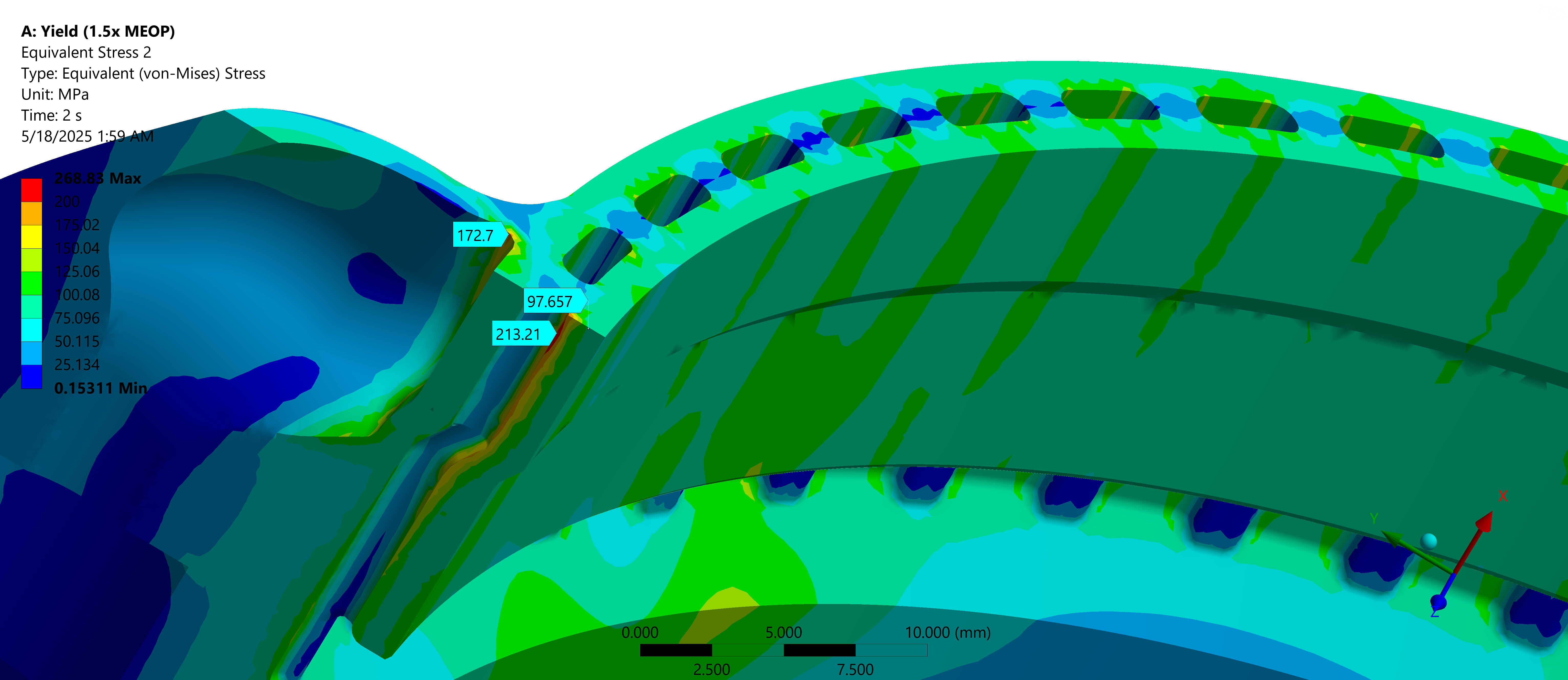

ANSYS structural analysis showing stress distribution under 2x MEOP ultimate loading conditions

High stress locations identified for optimization

CFD Analysis Results:

Structural Analysis Results:

Material Selection:

Completed comprehensive material trade study considering thermal conductivity, manufacturability, and structural properties. Selected AlSi10Mg aluminum alloy for optimal balance of thermal conductivity and additive manufacturing compatibility.

Manufacturing Drawings:

Created detailed technical drawings for metal 3D printing and post-processing operations, ensuring design manufacturability and quality control.

Production Coordination:

Coordinated with manufacturing sponsor to optimize design for additive manufacturing processes and machining operations.

Manufacturing Process:

The design was optimized for metal 3D printing using AlSi10Mg aluminum alloy by XMAKE, with detailed post-processing drawings for machining operations to ensure dimensional accuracy and surface finish.

Key Achievements:

Skills: ANSYS Fluent CFD, ANSYS Structural Analysis, SolidWorks CAD, Additive Manufacturing Design, Material Selection, Manufacturing Coordination, Technical Documentation